High speed line scan imaging

The SW-2001Q-CL camera outputs 4 x 2048 pixel resolution at 19,048 lines per second, while maintaining image quality at a signal-to-noise ratio of 58 dB.

Supreme RGB color reproduction

In JAI’s multi-sensor color line scan cameras, the coatings on the prism efficiently filter the RGB light spectrum to each individual sensor, providing steep spectral curves that minimize color “crosstalk” for supreme color precision.

Line scan images free from halo effects

Prism technology makes it possible to view the red, green, blue and NIR channels through a single optical plane. This method eliminates off-angle viewing problems, spatial compensation, and other issues that can be associated with tri-linear camera technology.

Features

Specifications

Sweep+ Series

SW-2001Q-CL

Line Scan

Multispectral

4-Bands R-G-B + NIR

N/A

2048 x 1 px

19 kHz

N/A

Camera Link

4xCCD RGB/NIR

N/A

28.7 mm

14.0 x 14.0 µm

Global shutter

28.7 mm

28.7 mm

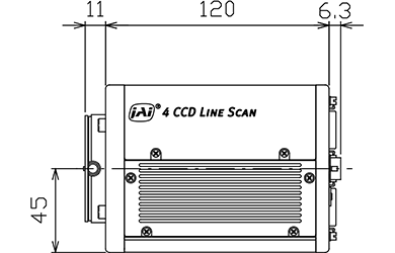

90 x 90 x 120 mm

1050 g

8/10-bit

F-mount or M52-mount

15.6 Watt

-5°C to +45°C

Downloads

Manual & datasheet

Compliance documents

Typical applications where Sweep+ Series industrial cameras are suitable

The Sweep+ Series line scan cameras are the ideal choice if you have imaging applications where you need very accurate RGB colors combined with simultaneous NIR imaging.